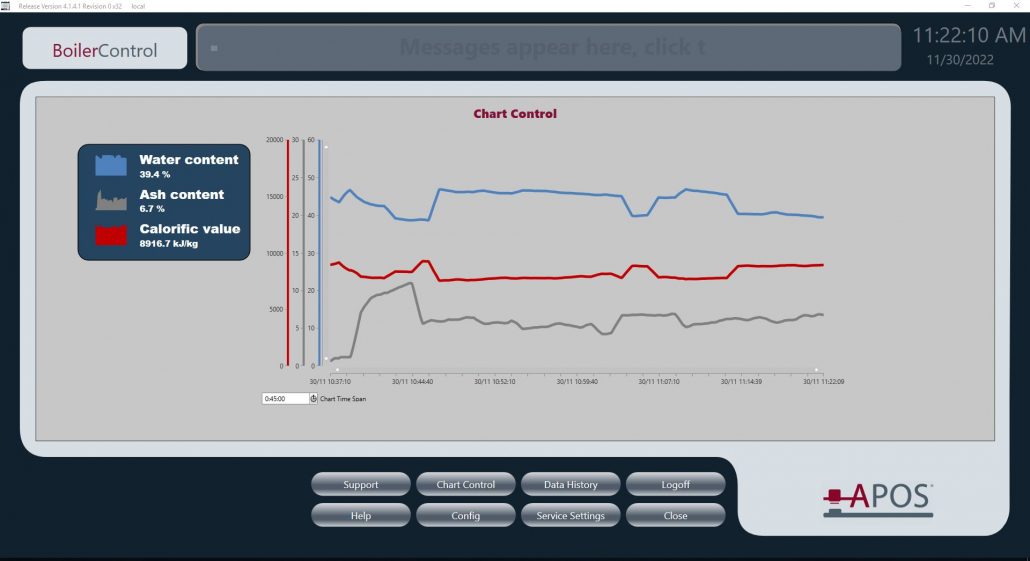

By transferring these parameters to the boiler control system, a more stable, efficient and economical boiler operation becomes possible. A smoothed and higher average steam/heat and possibly electricity production can be realised. The overall efficiency can be increased and the emission output reduced if necessary.

Online measurement of fuel quality enables automated fuel supply according to calorific value instead of mass or quantity flow.

Determination of water content, ash content and calorific value using purely optical NIR technology and the APOS analysis solution.

The sensor is installed in the fuel supply and the APOS application software is connected to the process control system via a standard interface. The process control system performs the optimisation with the help of the measurement data provided. The DCS always remains the leading system.

Fulfilment of reporting requirements on efficiency for the supervisory authority automatically!

Determining the total amount of primary energy fed into the boiler!

In many European countries, the authorities require accurate information on the total energy fed into the boiler to determine the efficiency of the installation. BoilerControl can measure calorific value, volume and mass flow and provides the total energy fed into the boiler!