Classic Taber test – hardly meaningful

by Heinrich Unland

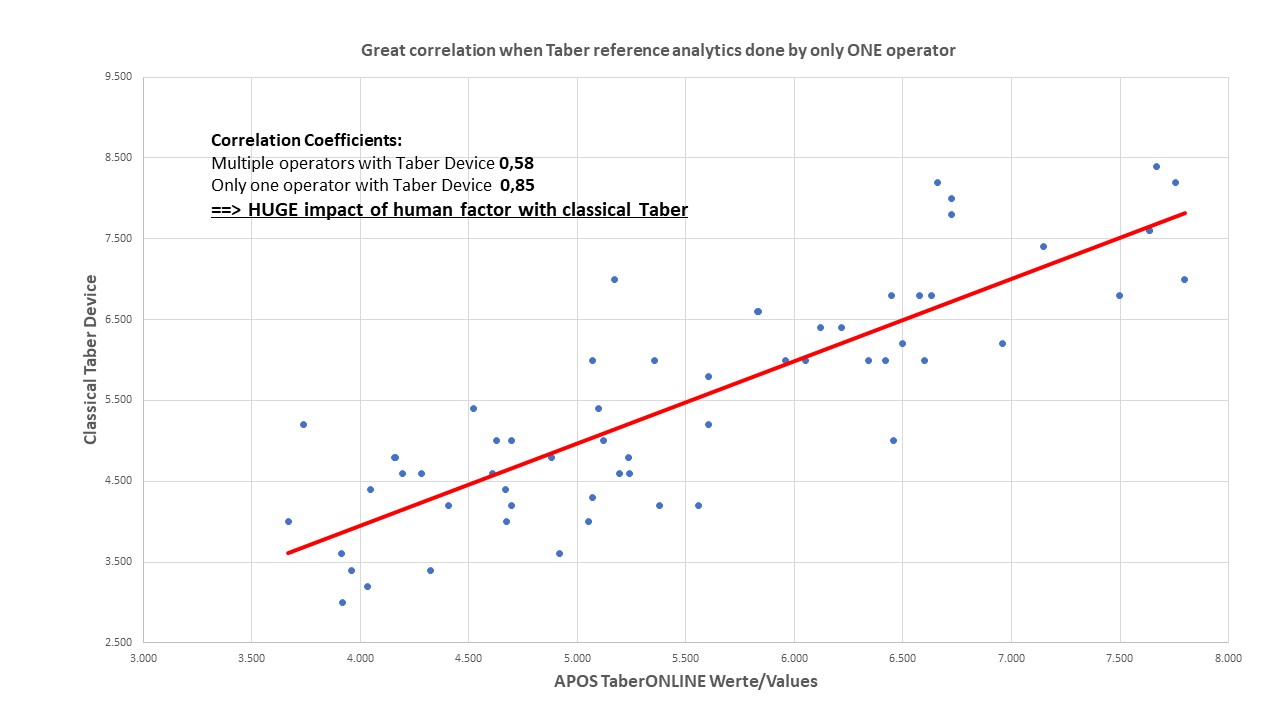

With TaberONLINE, APOS has developed an NIR system for real-time determination of the Taber abrasion class. During development, a four-digit number of classic Taber tests were carried out to set up the calibration databases.

Taber is subjective

The assessment of the degree of abrasion with classic Taber test is subjective. Each user assesses the result slightly differently and other external influences – lighting, fatigue, etc. – have an impact on the assessment of the Taber result.

At the beginning of the calibration campaign, there were deviations that could hardly be explained by material fluctuations. After extensive research into the cause, it became clear: the quality of the calibration and thus measurement results increased significantly if only one quality assurance officer had carried out the Taber test. A conclusion that seems obvious in hindsight, but:

For example, is AC4 actually AC4?

Or AC5 or even just AC3? In each customer plant, different quality inspectors are always busy with Taber tests. This can hardly be avoided due to the normal shift system. Due to the subjective nature of the test, however, different testers come to different conclusions with the same materials. APOS can prove this empirically.

Can a customer really rely on manual Taber testing? You don’t know!

The question is undetermined and depends on the QA team and the human, different assessments. There is still a great deal of doubt that a high financial test effort is being driven with dubious results. In the worst case, inferior material is produced, does not fail the test, but is later complained about by the customer. A financial meltdown.

Objective Taber Test with TABERonline

Technology is objective. Human errors are avoided by our TaberONLINE system, the calibrations underlying the systems are largely free of human influence. Our system does the Taber measurement in real time. Without material destruction. It recognizes immediately (!) if the quality is not sufficient or if too much corundum has been added. It warns if the proportion of corundum is too small and jeopardizes the quality. Without fatigue.