Inline, but panel by panel

by Heinrich Unland

Measuring the degree of cure of melamine resin surfaces MFB.

APOS’ classic strength since 2010 has been the continuous measurement of parameters in wood and wood-based materials – starting with biomass and following the production chain. For just over a year now, APOS has also started to metrologically record batch processes, but of course still inline.

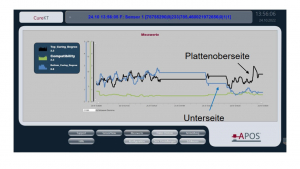

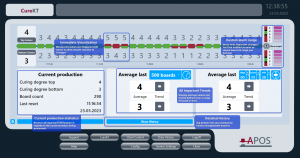

With the change in measuring points – away from continuous to single board – APOS has also completely rebuilt the visualisations. More intuitive, more user-friendly, recordable at a glance, with visual and or audible alarm when a set target corridor is left.

Classic APOS process visualization

New APOS visualisation for batch production – here with 2 sensors for top/bottom of the panel

With this new visualisation, APOS now has three families of visualisations available, for wood or biomass acceptance, for process applications and for batch production processes such as curing degree (CureKT), surface hardness for flooring (TABERonline) or other applications in panel production. Of course, all interfaces to third-party systems are retained for the new applications!