Application Note: NIR Measurement of refuse derived fuels: Part 2

6. Typical applications of NIR spectroscopy for RDF

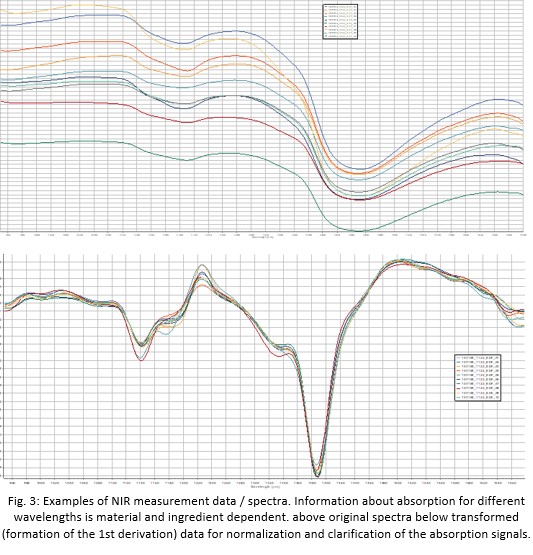

NIR systems process a reflection signal and absorbance information for different wavelengths (fig. 3). This material and ingredient dependent data can be used to determine different properties:

- Determination of calorific value: NIR spectroscopy can determine the calorific value of RDF materials, which is of central importance for energy production.

- Foreign Substance Identification: The method enables the detection of unwanted contaminants or non-combustible components in the RDF materials.

- Moisture content: NIR spectroscopy can measure the moisture content of RDF materials to optimize combustion efficiency.

- Sorting and classification: RDF materials can be sorted using NIR spectroscopy and classified according to their composition and energy content.

7. Best practices for measuring RDF materials using NIR spectroscopy:

- Calibration: Precise calibration of the NIR spectrometer is essential to achieve accurate measurement results.

- Representative Samples: Choosing representative samples for calibration and validation ensures reliable analytical data.

- Clean surfaces: The samples to be analyzed should be free of contamination in order to obtain correct measurement results.

- Periodic Validation: Regular validation of NIR spectroscopy by comparison to reference methods is important to verify accuracy.

- Data Analysis: Implement appropriate data analysis techniques to extract meaningful information from the NIR spectra, such as chemometric models and multivariate analysis.

8. Conclusion

NIR spectroscopy is a powerful technique for measuring RDF. Their ability to be non-invasive, efficient and environmentally friendly makes them a valuable tool for quality control and process optimization in waste-to-energy. Through careful calibration and adherence to best practices, NIR spectroscopy can help support the transition to sustainable and resource-efficient energy generation.