Process monitoring of laminate flooring production through continuous inline measurement of abrasion resistance and degree of cure

by Dr. Peter Nilges

1. Initial situation: Quality assurance of laminate

Laminates must meet certain product specifications in accordance with the intended use (e.g. flooring). As a quality criterion during production, the wear resistance and the degree of hardening of the cured wear coating are therefore determined. These parameters are currently determined at regular intervals at the end of the manufacturing process. For this purpose, a plate must be discharged from the process and tested using a material-destructive method.

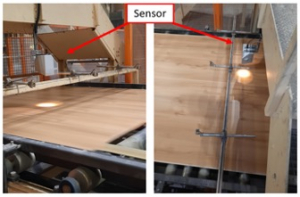

This time-consuming and costly procedure can now be replaced by a newly developed spectroscopic measuring system (Figure 1) from the company APOS. The measuring systems are based on the principle of optical spectroscopy and determines the wear resistance and the degree of hardening close to the process, continuously and non-destructively.

Figure 1: Example of an installed sensor

2. Optical spectroscopy: measurement of material properties by means of reflection

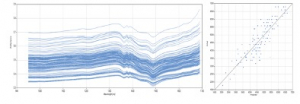

Optical spectroscopy (here NIR spectroscopy) is based on an interaction between electromagnetic radiation and the measured material. The detected signals (spectra, see figure 2, left) are based on a material- and content-dependent absorption of the radiation and provide important information about the measured sample. The molecular bonds of the various components are excited in the wavelength range used. Depending on the compounds in the material under investigation, certain wavelengths are absorbed. The recorded measurement data (absorption or reflection spectrum Figure 2, left) are linked to the reference values (desired measurement parameters, in this case abrasion, degree of cure) and correlations are determined or calibration models are developed (Figure 2, right). If the correlation is sufficient, a calibration model can be used to spectroscopically predict the parameters of an unknown sample. This means that measured values are accessible online and without sample preparation.

Figure 2: Left: NIR spectra (absorption or reflection vs. wavelength). Right: Plot of the regression line, system (predicted) vs. laboratory values (actual).

NIR spectroscopy is used by APOS in many industries, especially in the wood industry, e.g. to monitor the drying process by determining the water content, to determine wood species or nitrogen contents or to measure the molar ratio in glue. The newly developed measuring system can now be used to optimize the process for manufacturing flooring panels.

Figure 3: Visualization of parameters with measured value, target value and limit range

The current procedure and the very time-consuming and material-intensive method (taber-abraser test, acid test) for determining the wear resistance or the degree of curing is replaced by an online measurement. Here, the current measured values, the target value and a defined limit value are displayed with the software (Figure 3). As soon as the limit value is exceeded, a warning can be issued (visually or acoustically). Production can be monitored and immediate action can be taken if problems are detected.

In laminate flooring production, the online measurement of wear resistance can also be used to reliably infer the amount of corundum, with the possibility of avoiding over- and underscattering with considerable potential cost benefits.

2.1 Calibration development

For a reliable measurement, a calibration model with an extensive database is essential. APOS often develops new models and applications in cooperation with customers, where the customer does not need to have spectroscopy expertise. Calibration development takes into account possible production states. Thus, measurement data with different pressing time, temperature, pressure and corundum quantity were recorded. In addition, a large number of different decors (examples in Figure 4) were included in the database. In order to obtain variations of wear resistance and resin curing, products were specifically produced using a laboratory press (Figure 5). In addition, the measurement system was installed in a production plant for data acquisition. After spectroscopic measurement, analytical values were determined and calibration models were calculated.

Figure 4: Laboratory press for the production of laminates

3. Wear resistance and scratch resistance quality parameters of laminate flooring with complx determination method

Laminate floors must have a defined wear resistance and scratch resistance in order to be assigned to a product class. To improve the product properties, particles (e.g. corundum) are added to and incorporated into the resin layer. The protective layer (wear layer) protects the material from abrasion and wear. The abrasion resistance depends mainly on the amount of abrasion-resistant particles introduced into the wear layer and is routinely determined on a production line using a so-called Taber abrasion test.

In a Taber test, the resistance of the surface layer or wear layer to abrasion is tested. Samples (e.g. 10 cm x 10 cm in size) are cut out of the board to be tested. These specimens are clamped in a test fixture on which there are two swiveling arms with movable friction rollers and a weight (e.g. 500 g). The friction rollers are covered with standardized abrasive paper. The clamped specimens rotate under the friction wheels. Every 200 revolutions the abrasive paper is changed and the wear of the surface is tested. The test is completed when the substrate (printing base paper, primer) is visible in three quadrants of the specimen at a size of 0.6 mm2 each. The number of revolutions required to expose the decoration is indicated as the result. The higher the number of revolutions, the higher the abrasion class of the product.

With the new development, it is now possible to measure directly after the short-cycle press and provide abrasion values online. The measuring system (Figure 1) determines the parameters without contact and non-destructively. It is not necessary to eject a sheet and sample it. The measured variables that are now accessible are generated continuously and can be used for process optimization.

Figure 5: Examples of different decors

4. Curing level: : material hardening determines surface quality

Another important quality parameter of laminate flooring and also furniture boards is the degree of hardening of the resin. The material hardens in the pressing process and determines the surface quality of the product. Excessive curing leads to brittleness, which can cause cracking during further processing steps (sawing, drilling, milling, etc.). Too little curing can lead to poor surface properties in terms of resistance to chemicals and/or wear.

Until now, curing has been determined by means of the so-called acid test. In this test, the surface is exposed to a dilute mineral acid (4 molar hydrochloric acid) for a defined period of time. Subsequently, the gloss level and/or color change is subjectively assessed. The less loss of gloss/color is observed, the stronger the curing. However, this test also takes time, which leads to products not meeting quality requirements until the test result is available. As with the determination of the abrasion class, a sample must first be cut out of a larger panel (format: up to 2800 x 2070 mm). The plate from which the sample has been cut out must be sent to the second choice or scrap because of the cut-out. In addition, handling a semi-concentrated mineral acid is not entirely unproblematic, and certain dependencies of the result on the color of the decorative paper used also become apparent. This makes the evaluation more difficult, especially with very light decors and matt surface finishes.

Like wear resistance, the curing of the resin at the surface can also be measured continuously and objectively by means of NIR spectroscopy and used for process monitoring.

5. Advantages of continuous monitoring: description of costs and benefits of spectroscopic measurement

These currently used laboratory analysis methods are very time and material consuming and do not allow ad-hoc process optimization. With the newly developed APOS online systems, the laboratory methods can be replaced by spectroscopic measurements (optical spectroscopy).

This continuous analysis offers the following advantages:

- The amount of corundum can be reduced. By continuously monitoring the abrasion, the added corundum quantity can be adjusted to the target (abrasion class). So-called “fear surcharges” can be reduced; the savings potential is considerable, also for the manufacturers of the overlayer papers.

- Instead of randomly examining a small test specimen, a defined material surface is analyzed continuously (a new measured value every second).

- The process can be monitored. This makes it possible to increase production speed and identify production problems in good time.

- The laboratory procedure is no longer needed or only occasionally. Time and material can be saved. Chemicals of concern can be dispensed with.

- Non-destructive testing takes place. Material consumption for analysis and scrap is reduced.